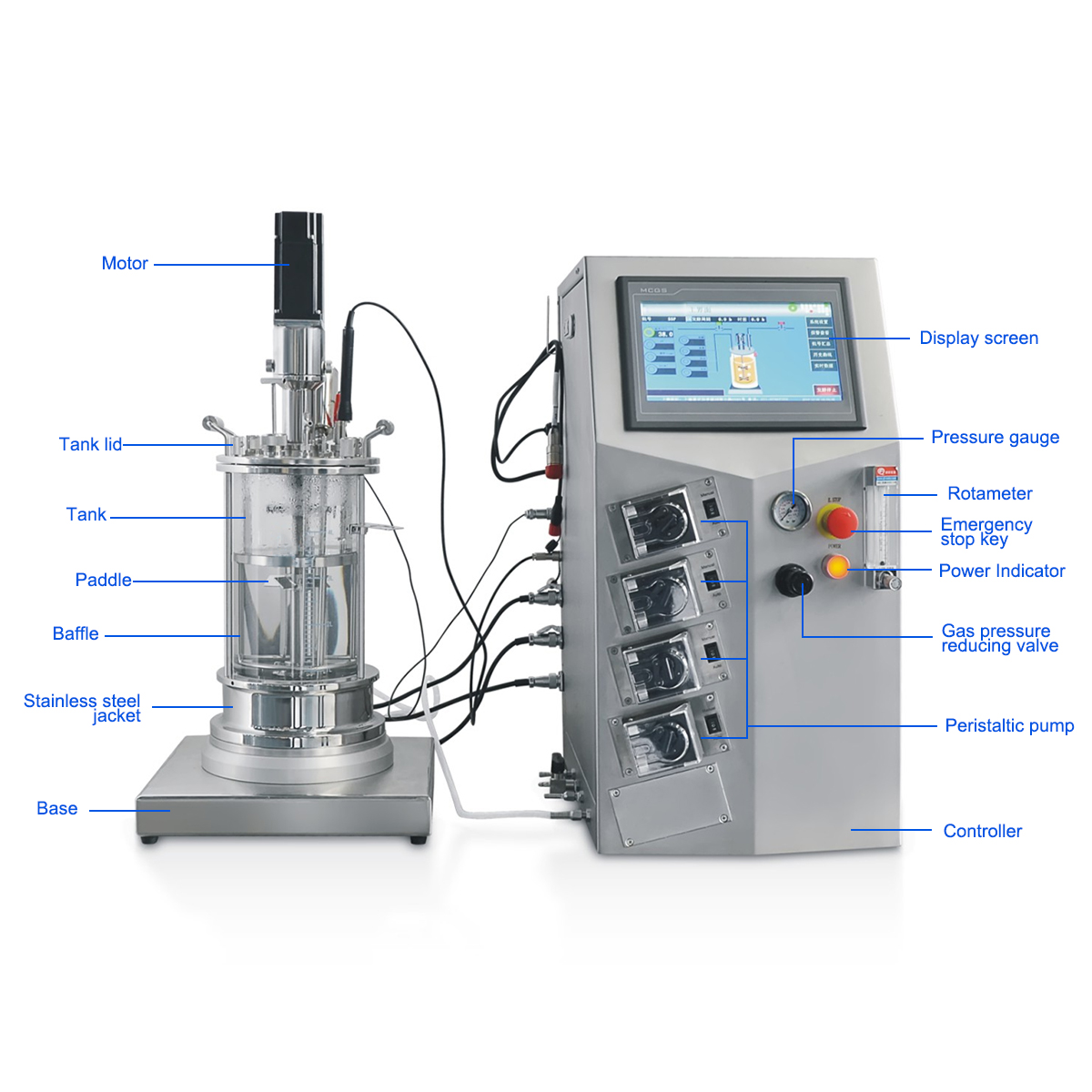

OVERVIEW

LBR-XGJG is a set of laboratory all-glass fermentation equipment, with off-site sterilization, oval glass tank bottom, mechanical stirring, convenient operation and powerful functions, which can meet the fermentation of various purposes, such as batch type, batch type flow addition, The single-arm tank is temperature-controlled by a heating blanket, and its volume is 0.5L, 1L, 2L, 3L, 5L, 7L, 10L, 15L and 20L.

It is the most cost-effective bioreactor, the temperature control and its accuracy can reach 0.05 ℃, and the color touch screen is used to display all measured values and control parameters, which greatly facilitates the user's operation. 4 peristaltic pumps are installed on the front of the control box, which can replenish the fermenter with acid, alkali, defoamer and medium. Various parameters in fermentation such as pH, DO, temperature and rotational speed can be monitored by the controller, and all data and control parameters can be transmitted to the controller or computer. The structure is compact, and various components can be integrated into the fermentation system. The structure design and configuration are completely consistent with the mainstream fermentation tanks in Europe.

Nominal volume: 0.5/1/2/3/5/7/10/15/20 liters

Diameter-height ratio: 1:2-3; Filling coefficient: 70%

Tank body: high temperature resistant, acid and alkali resistant, corrosion resistant borosilicate glass body and 316L stainless steel tank cover

Stirring method: Shaft-driven mechanical stirring (John Crane mechanical seal)

Ventilation: Rotameter display, adjust the flow of gas according to process requirements

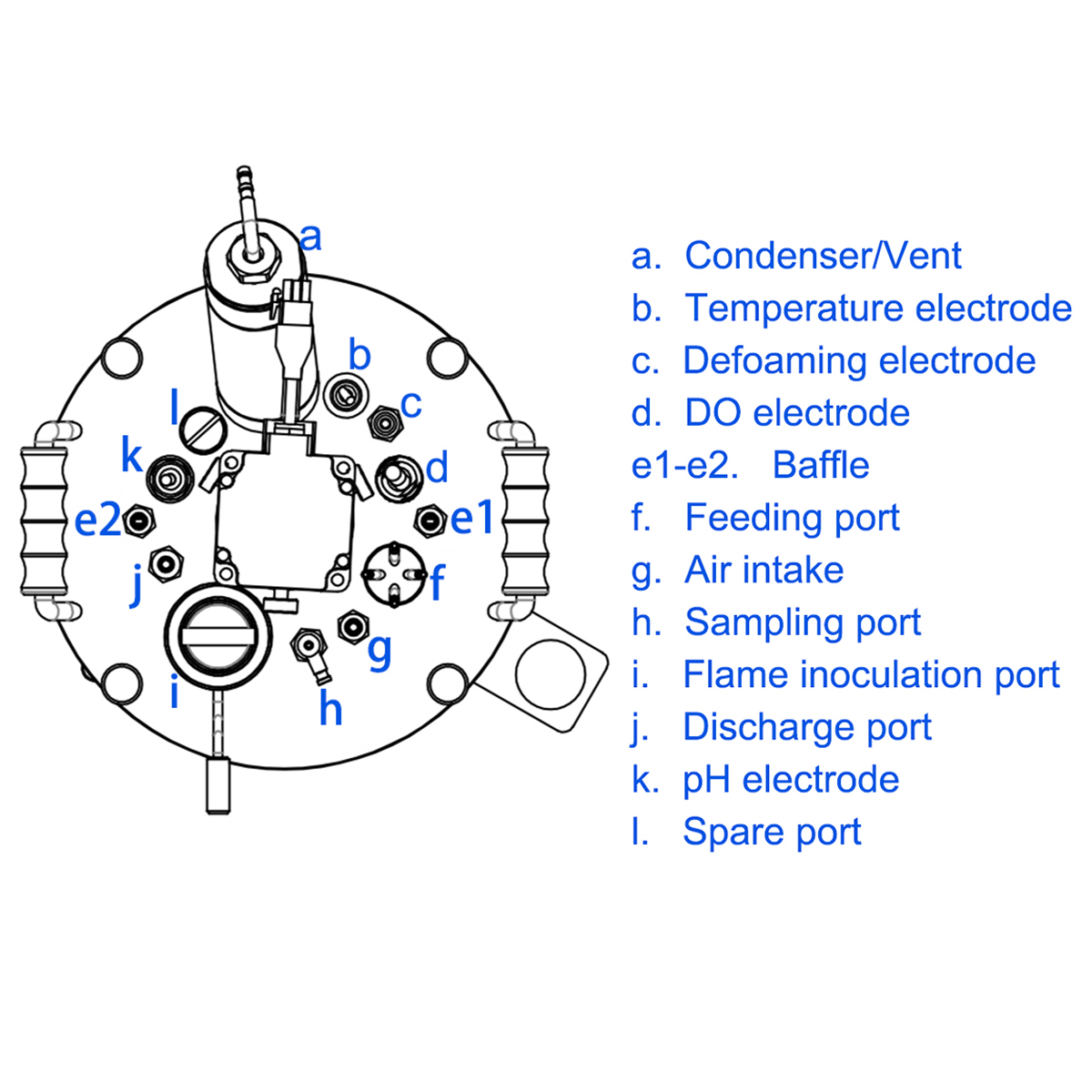

PH control function: intelligent PID control, Mettler PH electrode;

DO function: Mettler DO electrode, which can be controlled in association with feeding and rotating speed.

Temperature control: intelligent PID control, electric heating with heating blanket, water cooling with large-area cooling coil inside immersion, the accuracy can reach 0.05℃

Sterilization: Sterilization in a sterilizer;

Inoculation: flame inoculation and differential pressure inoculation;