In the biological reaction production process, the DO value is generally used as the dissolved oxygen parameter. The DO value is one of the most critical parameters in the entire fermentation process. It can not only intuitively reflect the dynamic changes of the entire fermentation process, but also indirectly reduce fermentation production time and energy consumption by increasing the DO value, and improve the yield and quality of the final product.

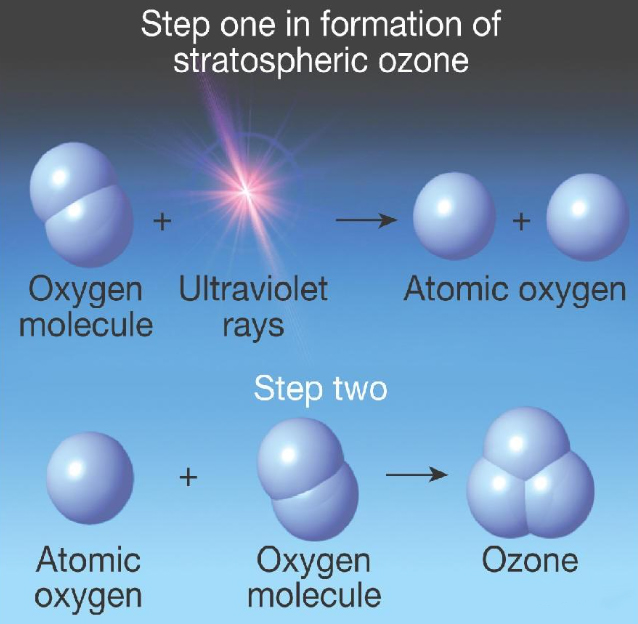

Dissolved oxygen is one of the most important parameters for aerobic fermentation control. Since the solubility of oxygen in water is very small, and the solubility in fermentation broth is even smaller, ventilation and stirring need to be constantly adjusted to meet the oxygen needs of different fermentation processes. The size of dissolved oxygen will have different effects on bacterial growth and product formation and yield.

Here, we will introduce the changes in dissolved oxygen concentration in different periods, the reasons for the abnormal decrease/increase in dissolved oxygen, and aspects of oxygen supply and oxygen consumption.

Changes in dissolved oxygen concentration

During the fermentation process, under certain fermentation conditions, the dissolved oxygen concentration of each fermentation product has its own rules. Generally, changes in dissolved oxygen concentration occur in three stages. In the logarithmic growth phase, the DO value drops significantly, and the growth of the bacteria can be roughly estimated from the rate of decline; at the end of the logarithmic growth phase, there will be a low point in dissolved oxygen; in the later stage of fermentation, due to the aging of the bacteria, the respiration intensity weakens, The dissolved oxygen concentration will also gradually increase. Once the bacteria autolyze, the increase in dissolved oxygen concentration will be more obvious.

Causes of abnormal decrease/increase in dissolved oxygen

During the fermentation process, sometimes there will be abnormal changes in the dissolved oxygen concentration that significantly decrease or increase significantly. There are many reasons, but essentially they are caused by the imbalance between oxygen supply and demand caused by changes in oxygen consumption or oxygen supply. Abnormal decrease in dissolved oxygen during fermentation may be due to the following reasons:

① Contaminated aerobic bacteria, a large amount of dissolved oxygen is consumed, causing the dissolved oxygen to drop to near zero in a short period of time

②Abnormal bacterial metabolism occurs, aerobic requirements increase, and dissolved oxygen decreases

③ Equipment or process controls that affect oxygen supply malfunction or change, causing a decrease in dissolved oxygen. If the stirring power consumption becomes smaller or the stirring speed becomes slower, it will affect the oxygen supply capacity and reduce the dissolved oxygen.

The main reason for the abnormal increase in dissolved oxygen is the significant decrease in oxygen consumption. For example, contamination with potent bacteriophages will inhibit the respiration of the production bacteria and increase the dissolved oxygen. When the bacteria rupture, they completely lose their respiratory ability and the dissolved oxygen will rise linearly.

Any change in DO value in the fermentation broth is the result of an imbalance between oxygen supply and demand. During the fermentation process, when the oxygen supply is greater than the oxygen consumption, the dissolved oxygen concentration increases; otherwise, it decreases. Therefore, to control the dissolved oxygen concentration in the fermentation broth, we need to start from two aspects: oxygen supply and oxygen consumption.

Oxygen supply

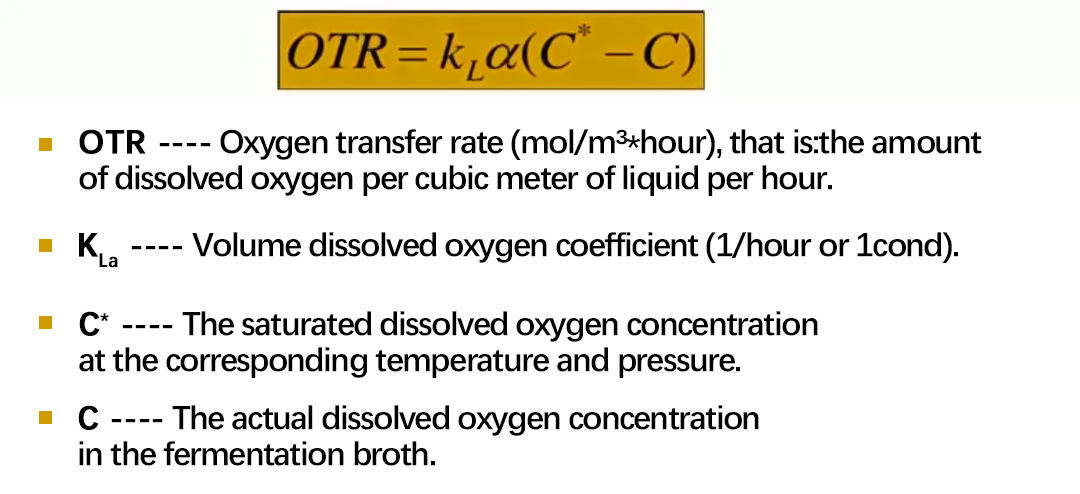

From the oxygen transfer rate equation OTR = KLα (c*-cL), it can be seen that any factor that can increase KLα and c* can improve fermentation oxygen supply.

Therefore, the main thing is to try to improve the driving force of oxygen transfer and the volumetric oxygen transfer coefficient KLα. The saturation concentration c* of oxygen in the fermentation broth is mainly affected by temperature, tank pressure and properties of the fermentation broth. These parameters are difficult to change under optimized process conditions. Therefore, in actual production, we usually start by increasing the volumetric oxygen transfer coefficient KLα of oxygen to improve the oxygen supply capacity of the equipment.

In addition to increasing ventilation, the stirring conditions are generally improved. By increasing the stirring speed or ventilation flow rate, reducing the viscosity of the fermentation broth, etc., the KLα value can be increased, thereby improving the oxygen supply capacity. Changing the stirrer diameter or speed can increase the power output and thus the alpha value.

In addition, changing the number and position of baffles can change the flow pattern of the fermentation liquid during stirring, which can also increase the α value. In recent years, methods to improve the oxygen transfer coefficient for biological applications by adding oxygen transfer intermediate media have attracted widespread attention. Oxygen transfer intermediate media include hemoglobin, paraffin, etc.

Oxygen consumption

The oxygen consumption in the fermentation process is affected by factors such as bacterial concentration, type and concentration of nutrient substrate, culture conditions, etc. Among them, the influence of bacterial concentration is the most obvious.

Controlling the specific growth rate of bacteria through the concentration of nutrient substrate, keeping it at a level slightly higher than the critical oxygen concentration for fermentation, and reaching the optimal bacterial concentration, is an important method to control the optimal dissolved oxygen concentration. For example, in penicillin fermentation, the concentration of bacteria is controlled by controlling the rate of glucose supplementation, thereby controlling the concentration of dissolved oxygen.

At present, the utilization rate of oxygen in the fermentation industry is still very low, only 40% to 60%, and in the antibiotic fermentation industry it is even lower, only 2% to 8%. The growth and metabolic activities of aerobic microorganisms require the consumption of oxygen, and they can only complete biological oxidation in the presence of oxygen molecules. Therefore, oxygen supply is essential for aerobic microorganisms.